An Automatic Power Factor Controller (APFC) Manager is a device used to manage and optimize the power factor in an electrical system. The power factor is a measure of how effectively electrical power is being used in a system. A low power factor means that the system is inefficient and requires more electrical power to perform the same amount of work. This can result in higher energy costs, increased electrical losses, and potential equipment damage.

The DakshIIoT’s APFC Manager works by continuously monitoring the power factor of the system and automatically adjusting the reactive power compensation to maintain a desired power factor. It achieves this by controlling the operation of power factor correction capacitors or reactors in the electrical system. These devices, when properly sized and operated, can help improve the power factor and optimize energy consumption.

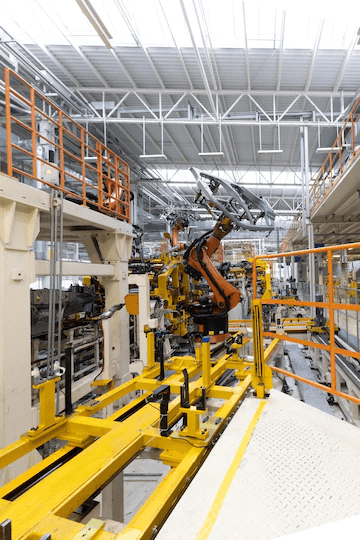

Implementing an APFC Manager in a factory can bring several benefits. Here’s how it works in a factory setting:

- Power Factor Improvement: The APFC Manager ensures that the power factor remains close to the desired value by automatically switching the capacitors or reactors as needed. This improves the power factor, reduces reactive power consumption, and minimizes penalties imposed by utility companies for poor power factor.

- Energy Efficiency: By maintaining a good power factor, the APFC Manager helps reduce the overall energy consumption of the factory. This leads to lower energy bills and improved energy efficiency.

- Equipment Performance and Lifespan: A poor power factor can cause voltage drops, overheating, and reduced efficiency in electrical equipment. By optimizing the power factor, the APFC Manager helps to improve the performance and lifespan of electrical equipment, such as motors, transformers, and generators.

- Increased Load Capacity: Improving the power factor can increase the effective load capacity of electrical distribution systems. This allows the factory to utilize its electrical infrastructure more efficiently and potentially avoid costly equipment upgrades.